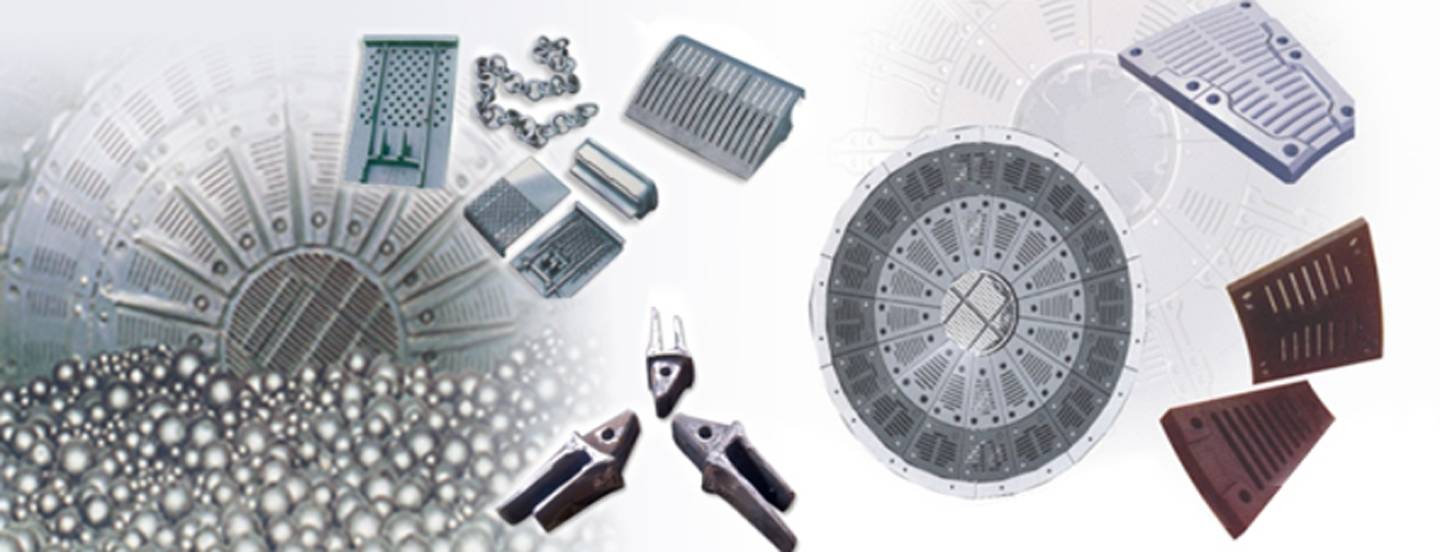

Grinding Ball

Overview

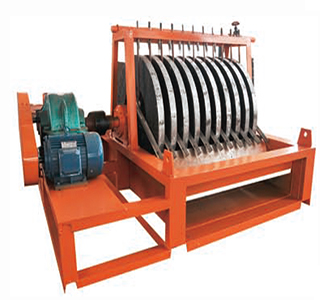

SNS Steel Balls are also known as ”general steel ball” in the field. These are made of SNS special steel which uses new materials containing no chrome. The Company produces SNS steel balls on its automated production line consisting of hot press and automated hot rolling device, among others, to maintain uniformity in the ball’s anti-abrasiveness, shape and hardness, and to achieve high quality.

Sizes

| Large | 150mm | 120mm | 100mm | 90mm | 80mm |

| Medium | 75mm | 70mm | 60mm | 50mm | 40mm |

| Small | 30mm | 25mm | 20mm | 17mm |

Application

for crushing of limestone in raw mill, raw materials in chemical factories and coal in power plants.

Overview

The Company has developed a new concept for steel ball beyond the conventional concept, which can be used for grinding of clinker at cement mill and replace the conventional high chrome casting steel ball, through the development of new materials and technologies.

Although the conventional high chrome casting steel ball offers an advantage of uniform hardness between the exterior and the interior, it contains high level of Cr causing the ball to break when dramatic thermal changes take place, and also the level of Cr contained therein is something one tries to remove for its harmful influence to the environment. Upon repeated researches and experiments over the last ten years in an effort to develop a steel ball that has advantages of forged balls and casting balls, the Company successfully developed an unprecedented steel ball of new concept.

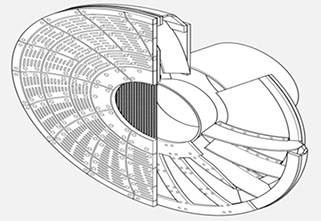

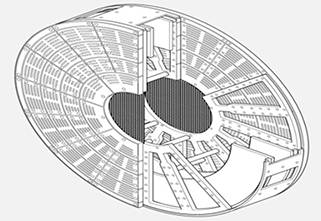

The Company named it ‘SNP steel ball’. SNP steel balls are manufactured using the hot press and the automated hot rolling device. Like the high chrome casting steel ball, SNP steel ball has virtually no variance between the internal and external hardness offering the same abrasion rate as the conventional high chrome casting steel ball, the same breaking rate as the conventional forged ball regardless of thermal changes as it is produced in the forging method, interchangeability with the conventional steel ball when used in a mill, and requires no replacement of liners thereby saving costs and making a significant contribution to cement manufacturing processes.

Sizes

| Large | 150mm | 120mm | 100mm | 90mm | 80mm |

| Medium | 75mm | 70mm | 60mm | 50mm | 40mm |

| Small | 30mm | 25mm | 20mm | 17mm | 15mm |

Application

To be used to crush raw rock and clinker at cement mill and mine, especially to crush hard rock.

Overview

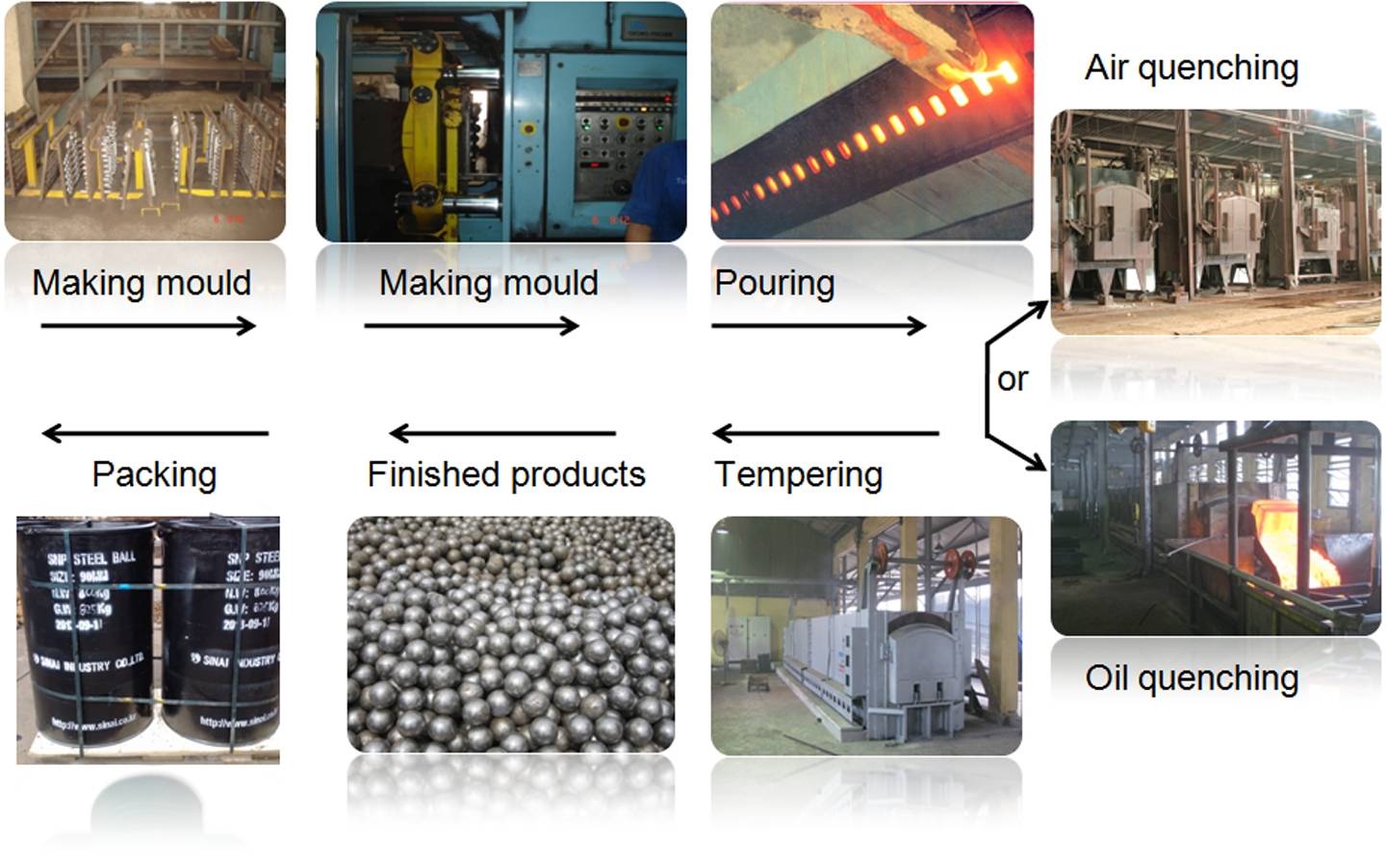

High chrome casting steel balls require a furnace to melt and evenly mix raw materials (such as C, Si, Mn, P, S, Cr, Ni) within the allowable limits applicable to each of the materials.

The formation of raw materials heavily influences quality of the finished product. For this fastidious reason, the Company only uses pure raw materials despite their high price, rather than recycled steel or used steel balls.

Sizes

| Large | 150mm | 120mm | 100mm | 90mm | 80mm |

| Medium | 75mm | 70mm | 60mm | 50mm | 40mm |

| Small | 30mm | 25mm | 20mm | 17mm | 15mm |

Application

To be used to crush clinker at cement mill.

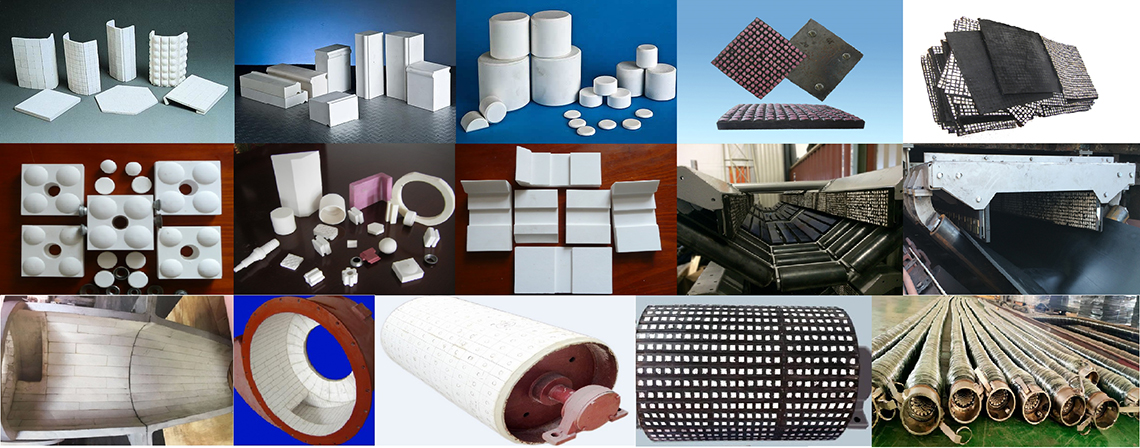

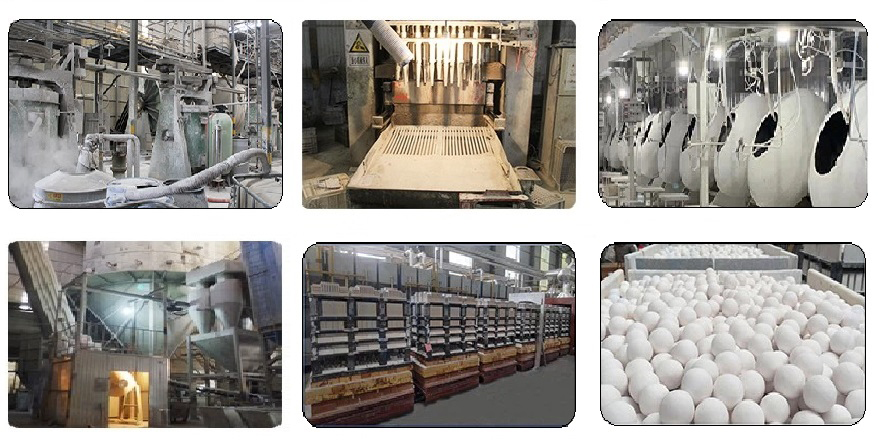

Overview

It is manufactured using a precise chemical composition and a well-controlled molding and sintering method using highly refined raw material powder. Due to the strong interatomic coupling force, the thermal expansion coefficient is small, can withstand rapid heat and rapid cooling, and is resistant to high temperatures. It has improved performance compared to conventional ceramics. It has high hardness, heat resistance, insulation, high wear resistance, and a long life, so it is used for grinding and dispersing in various high-tech industrial fields(electricity, electronics, abrasives, semiconductors, and chemical materials) and natural substances, foods, and pharmaceuticals that require minimization of contamination.

Sizes

| Large | 80mm | 70mm | 60mm | 50mm |

| Medium | 40mm | 30mm | 20mm | 17mm |

| Small | 15mm | 12mm | 8mm | 5mm |